How Are Contacts Made? 1800 Contacts

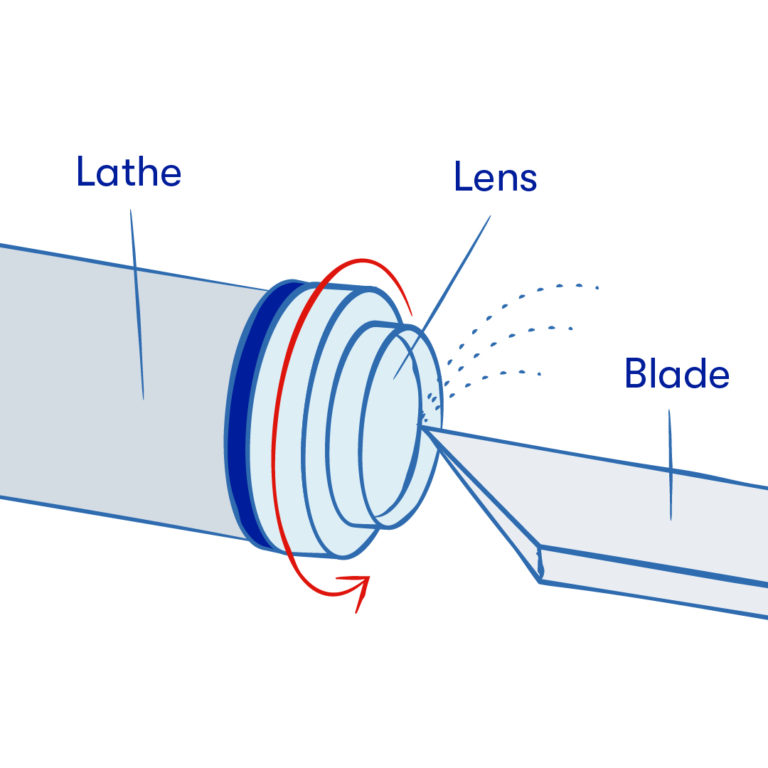

The process of lathe cutting starts with the small disks of raw plastic material which are placed on a rotating shaft. The shaft spins the plastic material at a high velocity while automated tools carve out the shape of the lenses. Once the shape of the lens has been made, the lenses are polished and hydrated in order to arrive at the soft.

How to Insert Soft Contact Lenses YouTube

The show is a documentary showing how common, everyday items (including foodstuffs like bubblegum, industrial products such as engines, musical instruments s.

How Its Made Contact Lenses YouTube

Contact lenses work by correcting vision through the use of a small, curved lens that sits directly on the eye's surface. The lens is designed to refract light in a way that corrects the eye's refractive error, which is what causes blurry vision. Contact lenses can be used to correct nearsightedness, farsightedness, astigmatism, and presbyopia.

What Are Contacts Made Of? Warby Parker

How Contact Lenses Work. Contact lenses are designed to capture and reflect light in a manner that corrects the way your eyes process light. Once the contact is in, it redirects light into a single focal point on the retina. It's similar to a magnifying glass. It fine-tunes and focuses the light that enters your eyes.

Electric contact lenses zoom in and out with the blink of an eye News The Times

Learn how to make contact lensesHow are Contact Lenses Manufactured?How It's Made.contact lensesMaking Contact LensesHow It's Made: Contact LensesHow Contact.

How To Insert And Remove Soft Contact Lenses Premier Optical

Both the cutting and polishing processes are carried out first on the concave inner surface and repeated on the lens' convex outer surface. After the front and rear surfaces are finalised, the lens is removed from the lathe and hydrated to make it softer. Quality assurance testing is performed on the finished lenses.

How Are Contact Lenses Made?

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright.

How to Put In and Take Out Contact Lenses

Contact lenses are made from a variety of materials, each with its unique properties. The modern manufacturing process involves 7 steps. Lens Shape and Design. Manufacturers must first design a contact lens that meets the specifications of the prescription. This process is based on factors such as the degree of refractive error, pupil position.

How It's Made Contact Lenses 3 YouTube

Injection molding. In this process, the soft contact lens material is heated to a molten state and is then injected into computer-designed molds under pressure. The lenses are then quickly cooled and removed from the molds. The edges of the lenses are polished smooth, and the lenses are hydrated to soften them prior to undergoing quality.

SPECIALIZED CONTACT LENSES De Jongh Optometry

Soft contact lenses can be made in one of two ways: Lathe cutting. This is a process where small, hard disks of contact lens material are placed on a spinning shaft like a miniature potter's wheel that rotates at 6,000 revolutions per minute and shaped with computerized cutting tools. Once created, the lens then goes through different stages.

Contact Lenses 101 Eye Care

On this episode of How It's Made, we learn all about the manufacturing process that goes into making Eyeglass Lenses.

Dos and Don’ts of Wearing Contact Lenses Affordable Contact Lens Beautifying the vision made

On this episode of How It's Made, we learn all about the manufacturing process that goes into making a Contact Lenses.

How Contact Lenses are Made YouTube

Soft, hard, and hybrid contact lenses are all made using types of plastic, but maybe not the kind of plastic that comes to mind when you hear that word. Different types of contacts are made using various high-tech polymers that allow oxygen to flow through to reach the cornea—a necessity when it comes to eye health.. In this guide, we'll examine the materials used to make contact lenses.

DIY CONTACT LENS SOLUTIONHOMEMADE LENS SOLUTION EASILY YouTube

In the production of contact lenses, the lens material is heated to the point of melting. The liquid lens material is then injected into a pre-cut mould. The material solidifies to the shape of the mould once the lens material dries. The lens will be polished, then inspected to check its standard of quality.

How to put in contact lenses SUPER easy (Method 1) YouTube

How It's Made is a documentary television series that premiered on January 6, 2001 on the Discovery Channel (now known as Discovery Science in Canada, and Sc.

HOW IT'S MADE Contact Lenses (UK Version) YouTube

Once your Optometrist has determined your prescription, as well as the diameter and the curvature of your cornea, the data is sent to the contact lens manufacturer that will be making your lenses. That data is entered into a computer that will control all of the machines used during the process. With lathe cutting, a cylinder of contact lens.